inagv Micro Servo Drive

With years of steadfast commitment and innovation, INAGV has achieved significant accomplishments in the field of motion control, becoming a leading provider of products and solutions. The company is dedicated to product innovation, continuously developing new technologies and optimizing product performance to meet the growing demands of customers. Additionally, INAGV actively expands its market and has established long-term partnerships with many excellent equipment manufacturers, exporting its products to numerous countries worldwide.

The stability, reliability, and superior performance of INAGV products are key factors in earning customer trust. Whether in the electronics, semiconductor, logistics, new energy, robotics, machine tool, or medical industries, INAGV's products demonstrate outstanding performance and stability, providing customers with reliable solutions.

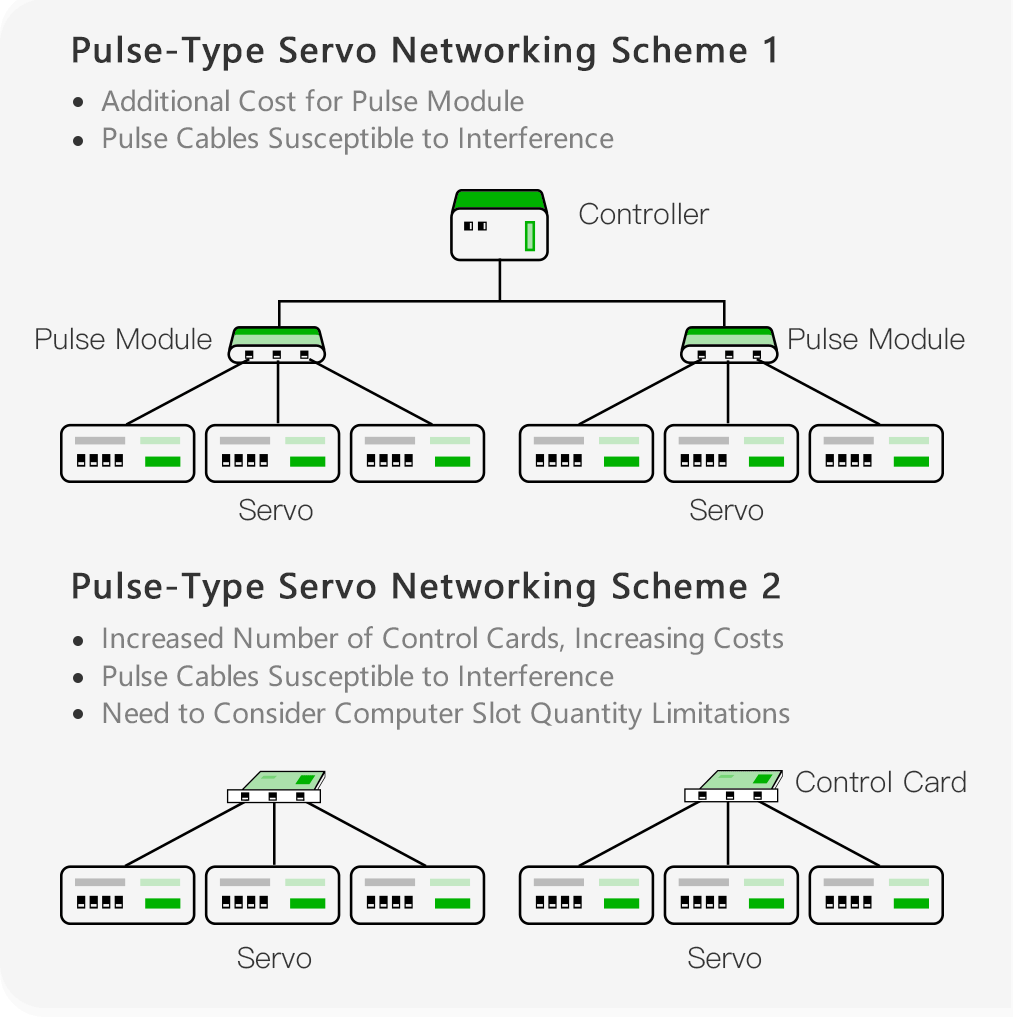

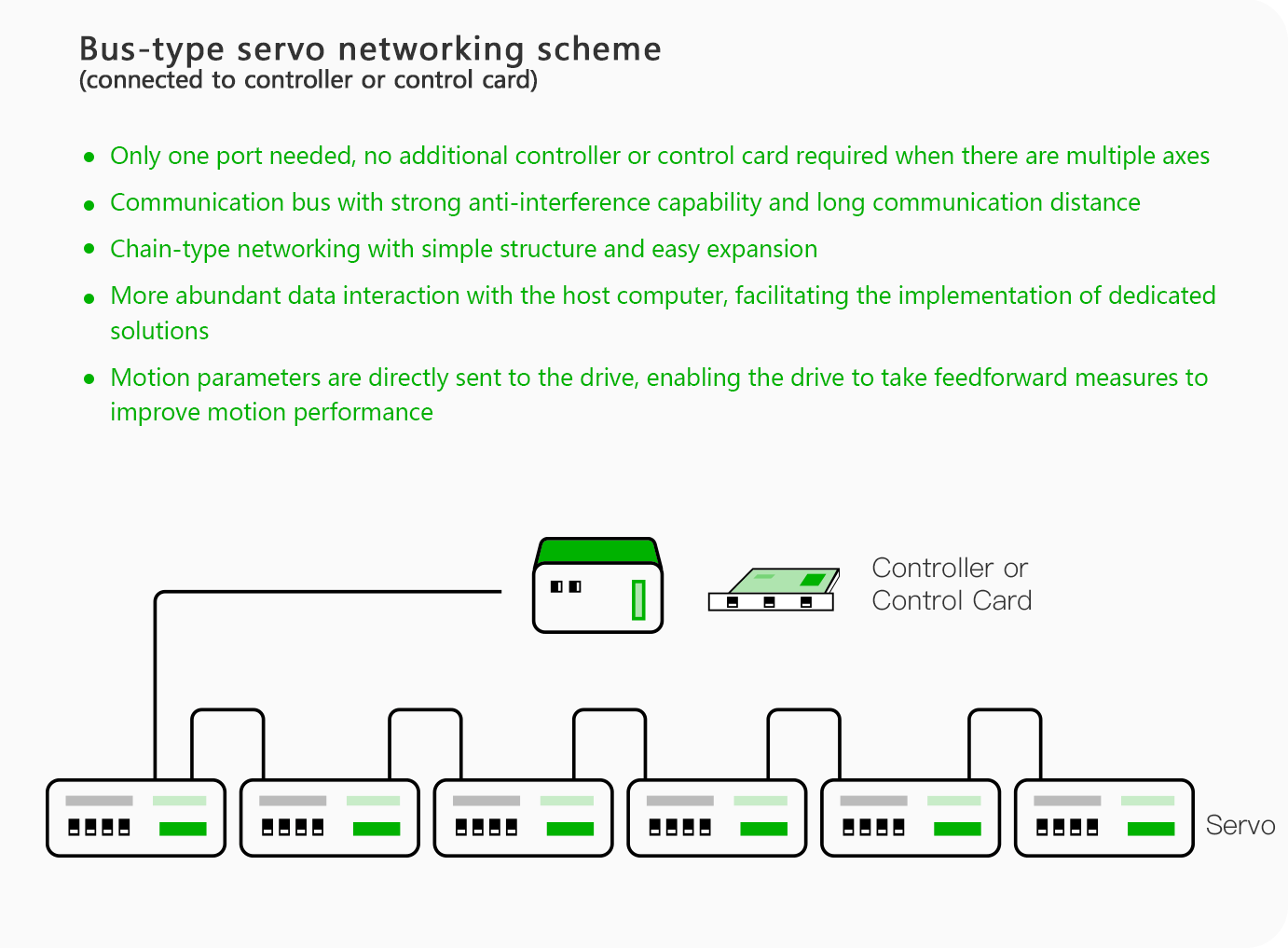

Compared with pulse-type servos, the PLD2L series AC servos have the following advantages

In pulse communication, the transmission lines of the pulse signal are susceptible to electromagnetic interference, reducing communication reliability. In contrast, CAN bus communication, with its built-in error detection, limitation, and processing mechanisms, can significantly improve communication reliability, reduce the impact of interference on commands, and extend communication distances.

n pulse communication, the controller needs to communicate with each drive through pulse cables, often resulting in dense and complex machine wiring. With CAN bus communication, the controller only needs to connect with one drive using a cable, and the remaining drives can be connected to this drive in a chain-like manner.

In non-periodic synchronous mode of bus communication servos, trajectory planning is implemented in the drive. The controller only needs to pass target position, speed, acceleration, and other information to the drive. Therefore, the drive can anticipate the next moment's motion parameters internally and take feedforward measures to improve motion performance.

Multiple bus-type servo drives only need one port to connect to the motion control unit (motion controller or motion control card), eliminating the need for pulse modules and additional control cards due to the large number of drives. This also removes the constraints of computer port availability, saving costs on pulse modules, control cards, and industrial PCs.

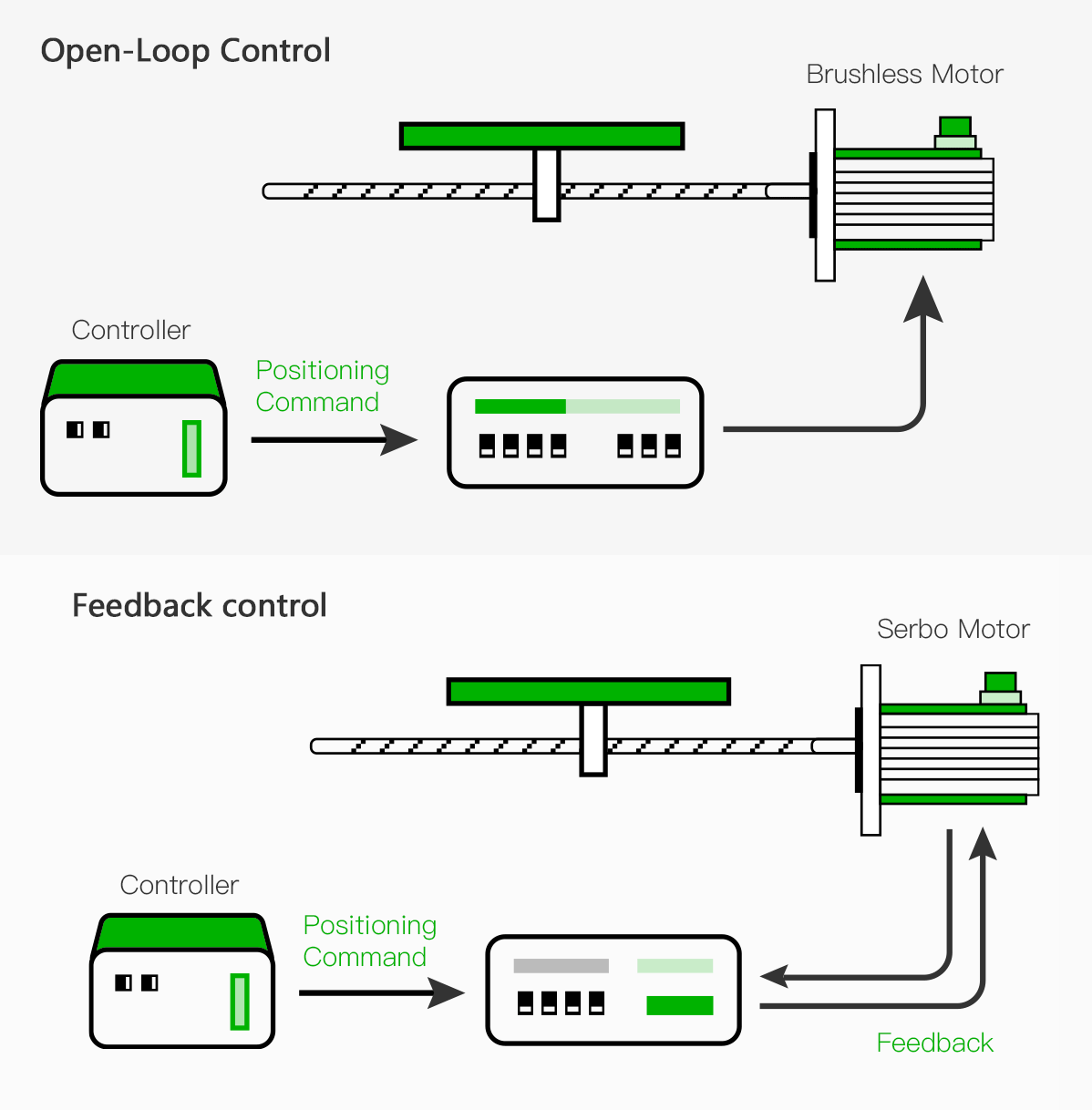

The servo motor comes with an encoder, and the position signal feeds back to the servo drive, forming a semi-closed-loop control system together with the open-loop position controller.

The speed ratio is 1:5000, maintaining stable torque characteristics from low to high speeds.

The maximum speed of the servo motor can reach 5000rpm, with a positioning accuracy of 1/10000r. Note: The maximum speed varies for different servo motor models.

By modifying parameters, you can adjust the working mode and operating characteristics of the servo system to meet different requirements.